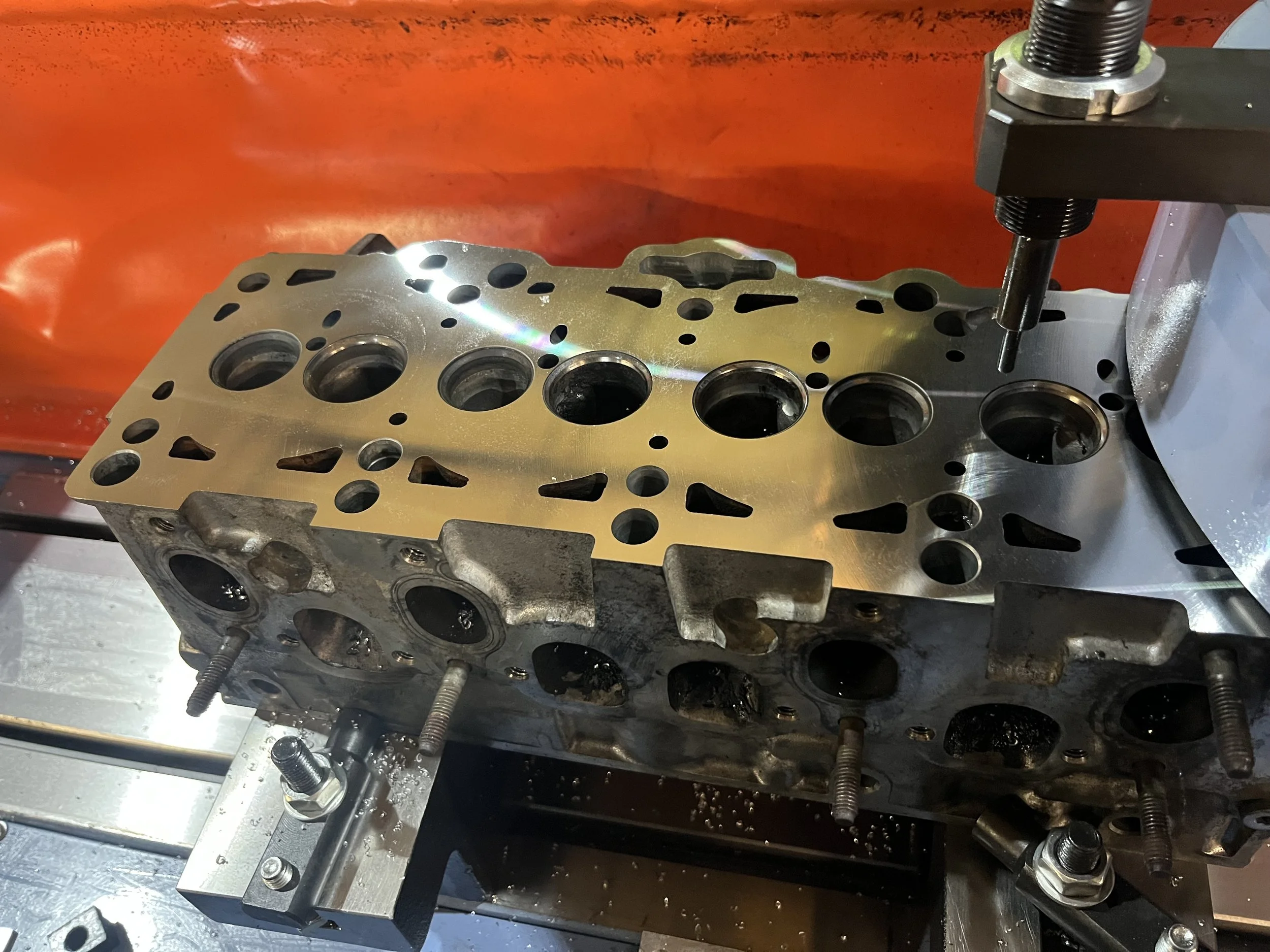

Pressure/Crack Testing

Pressure and crack testing of combustion engines is a vital diagnostic process used to identify leaks and failures within engine components, particularly cylinder heads. This procedure involves subjecting the component to high pressure while submerging it. Any bubbles that appear indicate the presence of cracks or defects. The aim is to ensure that the engine operates efficiently and reliably, preventing costly repairs and ensuring optimal performance. This testing is crucial for both modern and classic engines, as even minor flaws can lead to significant issues if left unaddressed.

Refacing

Refacing a cylinder head is a critical process undertaken to restore the flatness and surface finish of the cylinder head. This procedure involves removing a thin layer of material from the mating surface of the cylinder head to ensure proper sealing and fit with the engine block or gasket. This is essential for optimal engine performance, as it helps eliminate leaks and improves combustion efficiency. The refacing process is performed using specialized machinery that guarantees precision, ensuring the head meets manufacturer specifications. It is a vital step in the cylinder head repair and renovation process, aimed at extending the overall lifespan of the engine.

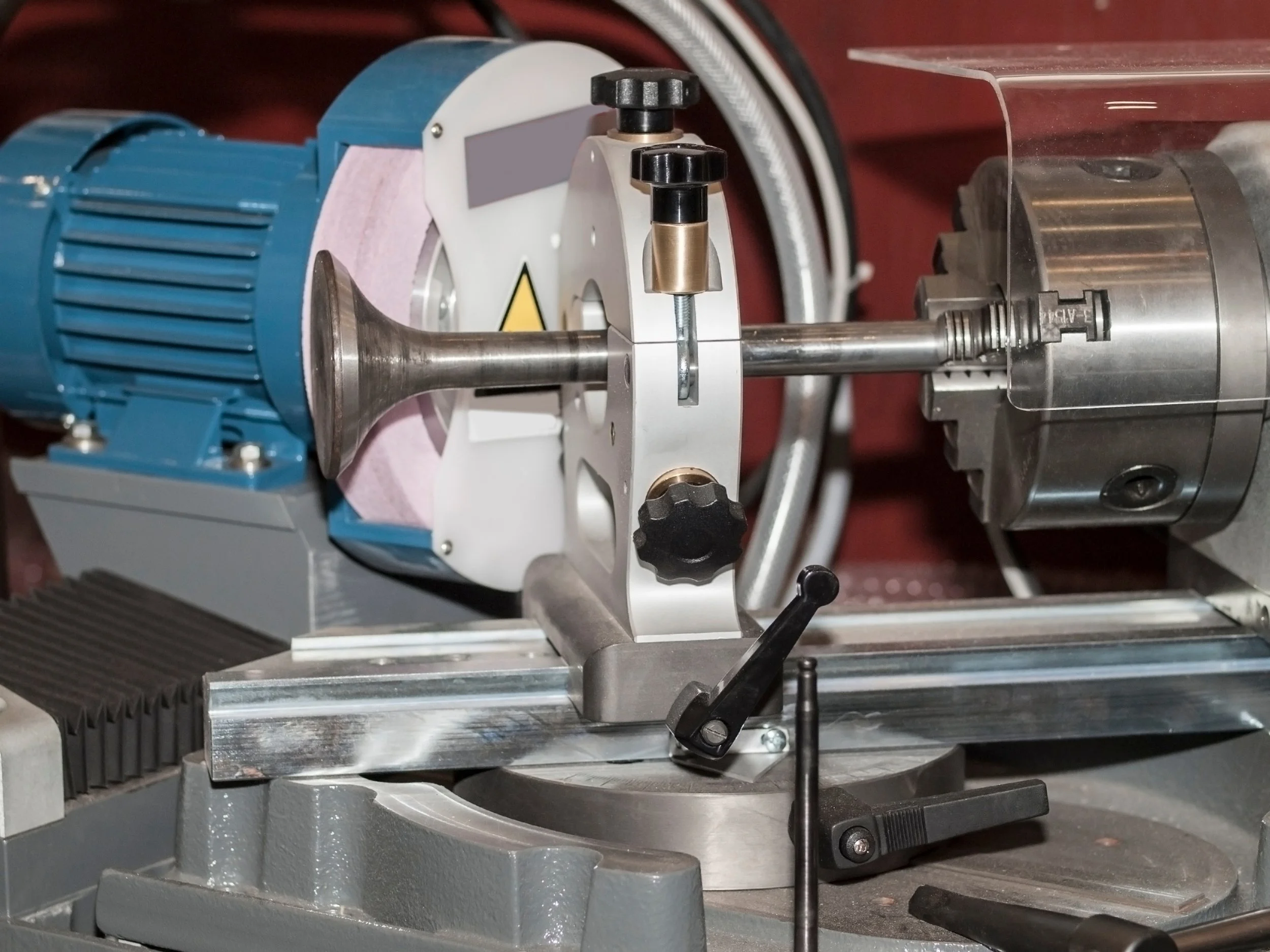

Valve and Valve Seat Grinding

This procedure involves precisely reshaping the contact surfaces of the valves and valve seats to ensure a tight seal, which is critical for optimal engine performance. During valve grinding, the end of the valve is ground against an abrasive material at a specific angle to create a smooth, flat surface. This is often paired with valve seat grinding, where the valve seat—the area within the cylinder head where the valve rests — is ground to match the valve's profile.

This process is particularly vital in both modern and classic engines, where precision and quality workmanship can significantly affect longevity and performance.

Valve and Valve Guide Replacement

Valve and valve guide replacement is vital for optimal engine performance and longevity. Valves control air and fuel flow and expel exhaust gases. Over time, they can wear or become damaged, impacting efficiency. The process involves removing old valves, inspecting valve seats and ensuring proper sealing. Worn valve guides, which maintain valve alignment, are also replaced. This procedure demands precision to ensure all components function effectively, boosting engine performance and reliability. Regular inspection and timely replacement can prevent significant damage and costly repairs.

Thread and Broken Stud Repairs

Thread and broken stud repair is an inevitable part of of workshop repairs. High temperatures and mechanical stress can cause thread wear or stud breakage. The repair process involves removing the damaged stud with specialized tools to avoid surrounding damage. After removal, the cylinder head threads are inspected and may need refinishing or helicoiling to fit new studs securely, ensuring optimal sealing and performance.

Exhaust Manifold, Flywheel and Cylinder Block Refacing

Exhaust Manifold Refacing - This process machines the manifold's surface to make it flat, ensuring a good seal with the cylinder head. This helps avoid exhaust leaks, improves performance, and cuts down emissions.

Flywheel Refacing - Resurfacing the flywheel's contact area makes it flat and smooth. This is important for better clutch engagement and driving performance, as well as improving torque transfer in both manual and automatic vehicles.

Cylinder Block Refacing - This process machines the cylinder block's top surface to ensure it is flat, which is crucial for sealing gaskets during engine rebuilds. A smooth surface helps prevent leaks and boosts engine reliability and lifespan.

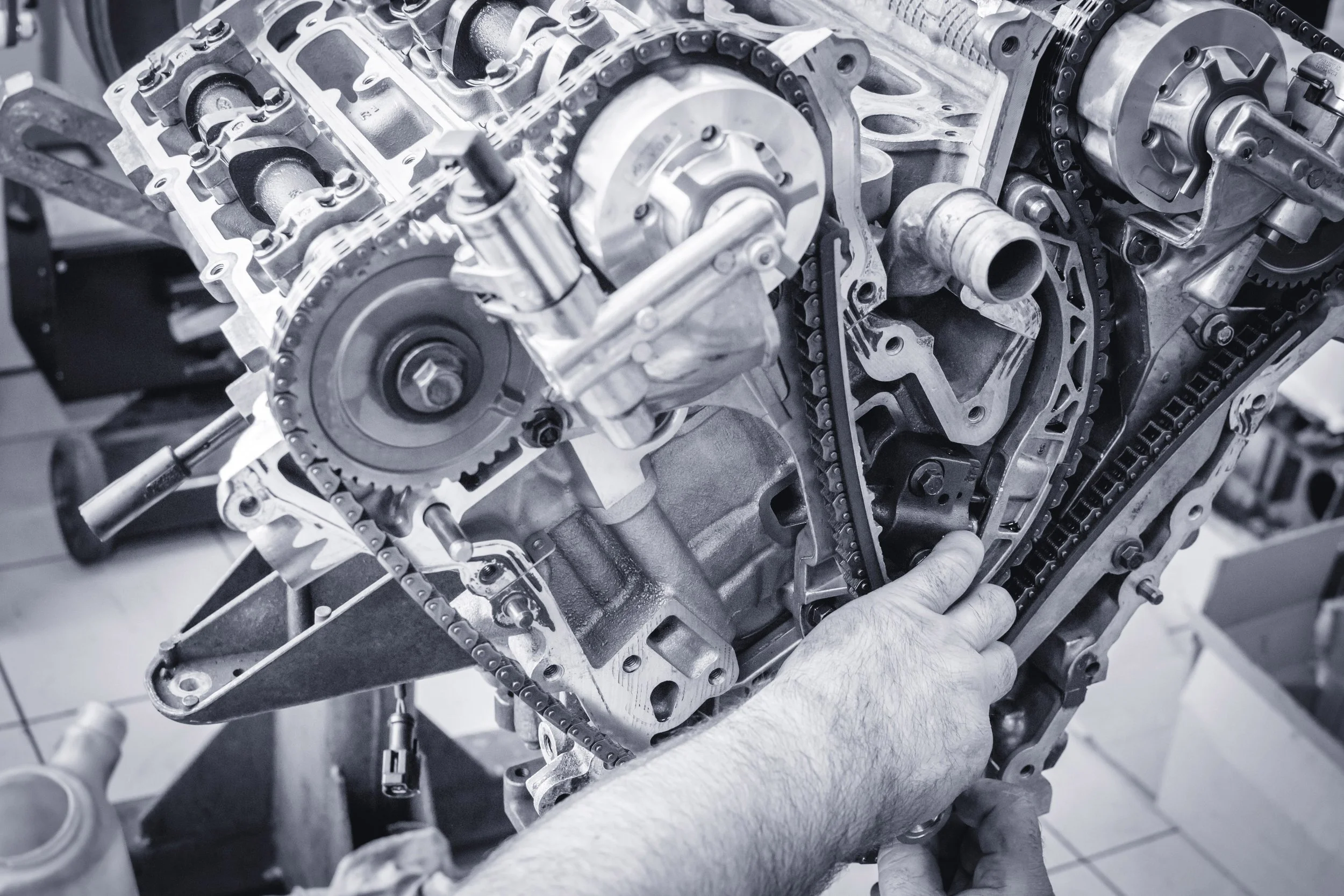

Engine Building

Our engine building services specialise in the comprehensive assembly and enhancement of combustion engines, tailored precisely to meet the specifications and performance requirements of our clients. We diligently source and utilize high-quality components, ensuring optimal functionality and durability. Our skilled technicians excel in configuring both modern and classic engines, meticulously addressing every detail from cylinder head renovations to crankshaft installations. Whether for performance upgrades, restorations, or custom builds, we are dedicated to providing exceptional engine solutions that ensure your vehicle performs at its peak.